- Home

- Core Drill Bits

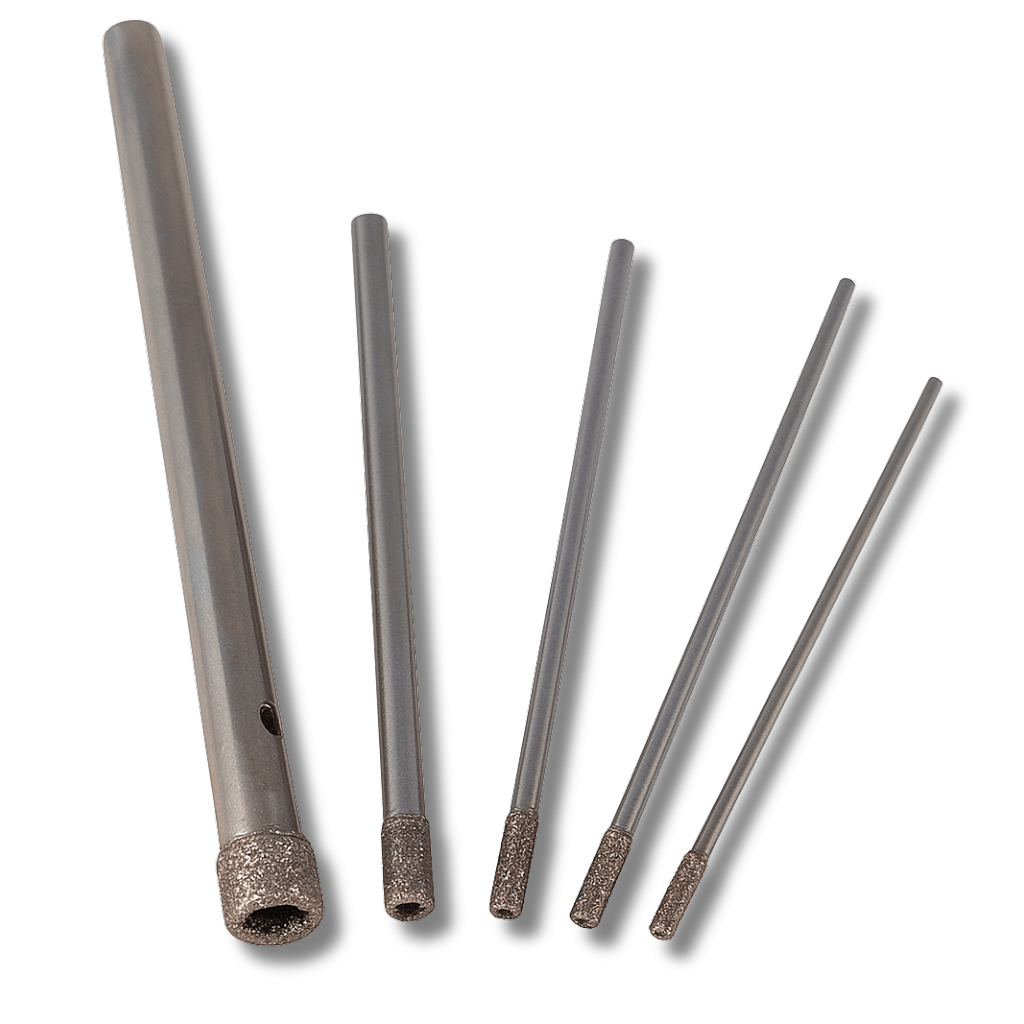

- Small Diamond Core Drills

Small Diamond Core Drills

Small Diamond Core Drills

Eternal Tools

SKU:SDCD1100

Drill clean, precise micro holes in glass, stone and ceramic (1–3mm). These Small Diamond Core Drills (1.0–3.0mm) are perfect for sea glass, beads, gemstones, porcelain, glazed pottery, pebbles, slate, optical glass and composites. The hollow core clears slurry, runs cooler and helps achieve chip-free entry/exit on brittle materials—ideal for jewellers and glass artists.

Best practice: Drill under water with the work supported on a rubber block. Run at slow to moderate speed (max 10,000 RPM) and use very light pressure, pulsing up and down to clear slurry.

Sizes: 1.0, 1.5, 2.0, 2.5, 3.0mm (select below). Bond: Electroplated diamond. Coolant: Water.

Usage Guide

1. Submerge the work on a rubber block in a shallow dish of water. 2. Mark the hole; start at a slight angle to create a bite, then level out. 3. Use light pressure; pulse the drill up and down to clear slurry, always keeping the crown wet. 4. Stay under 10,000 RPM. Deburr edges afterwards with a diamond ball burr if required.

Core vs Solid Diamond Drills

Core drills remove a tiny plug and run cooler on brittle materials—perfect for 1–3mm holes in glass and ceramic. For very hard materials (quartz, ruby, flint, fossil bone, porcelain) or when you need a solid end, use our Small Solid Diamond Drill Bits instead.

***Sold Individually*** See the Technical tab for exact dimensions and collet/chuck guidance.

Couldn't load pickup availability

Description

Description

What Are Small Diamond Core Drills?

These drills are hollow so water and slurry can move through the centre while cutting. That reduces heat, helps prevent cracks, and extends tool life—ideal for clean micro holes in sea glass, tile, beads, beach pottery, ceramics and similar materials.

Some makers also use them to extract tiny cylindrical cores for laboratory samples or beads. Results vary by material; keep everything wet and clear the core frequently.

Rotary Tool/Dremel Compatibility

You’ll need an adjustable chuck. For Dremel, we recommend the Dremel 4486 Multi Chuck for quick changes.

Top Tips for Best Results

1. Keep the work submerged in water and change the water if it turns cloudy. 2. Run at a slow–moderate speed (maximum 10,000 RPM). 3. Apply light pressure; pulse the drill in and out to clear debris and avoid forcing it.

Guides & Tutorials

12 Things You Should Know About Diamond Drill Bits | How to drill sea glass | How to drill pebbles | How to drill glass (infographic)

When to Choose Solid Diamond Drill Bits

If you’re drilling very hard materials (quartz, flint, thick shell, porcelain or high-Mohs gemstones), choose our Small Solid Diamond Drill Bits for better durability and coverage.

Need larger holes? See our Diamond Core Drills 3.5mm–65mm.

Safety

Disclaimer: Using rotary tools near water has not, to our knowledge, been endorsed by any rotary tool manufacturers. If you choose to drill with attachments submerged or near water, you do so at your own risk. Electricity and water can be dangerous.

Technical

Technical

Diamond grit 120# is precisely electroplated onto a hardened steel shank

1.00mm Diameter core drill

- Overall length: 60mm

- Diamond working length: 3.0mm - 5.0mm

- Shank: 0.75mm

- Tolerance +/-0.1mm

1.50mm Diameter core drill

- Overall length: 65mm

- Diamond working length: 6.0mm - 8.0mm

- Shank: 1.48mm

2.00mm Diameter core drill

- Overall length: 65mm

- Diamond working length: 4.0mm - 6.0mm

- Shank: 1.50mm

2.50mm Diameter core drill

- Overall length: 65mm

- Diamond working length: 5.0-6.0mmmm

- Shank: 2.0mm

3.00mm Diameter core drill

- Overall length: 50mm

- Diamond working length: 4.0mm

- Shank: 2.70mm

- Tolerance +0.1mm

Customer Reviews

Customer Reviews

Delivery popup

£3.99 delivery via 1st Class Post

FREE on Orders over £60

Orders placed before 3pm despatched same day

£8.99 delivery next working day on orders placed Mon - Thurs before 3pm