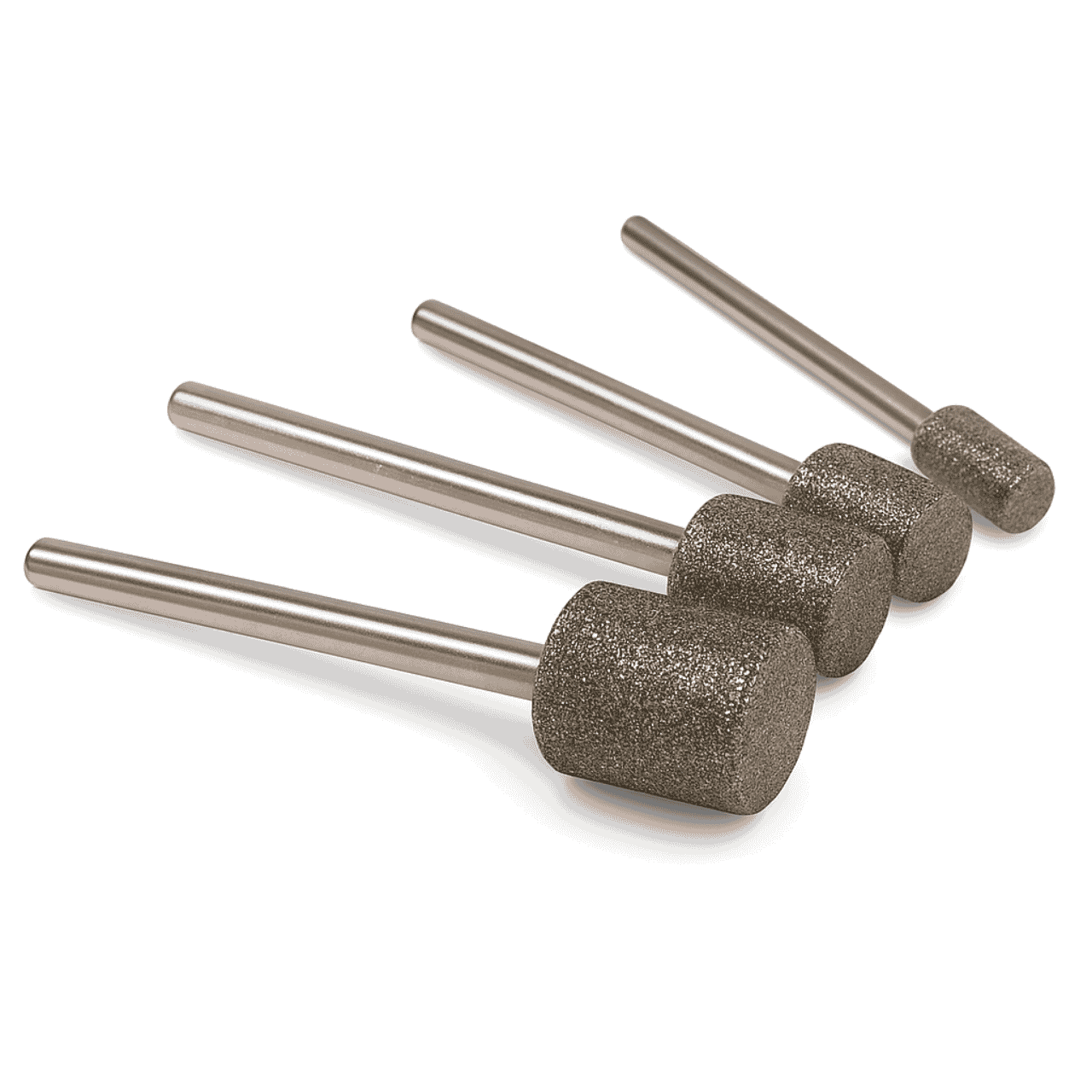

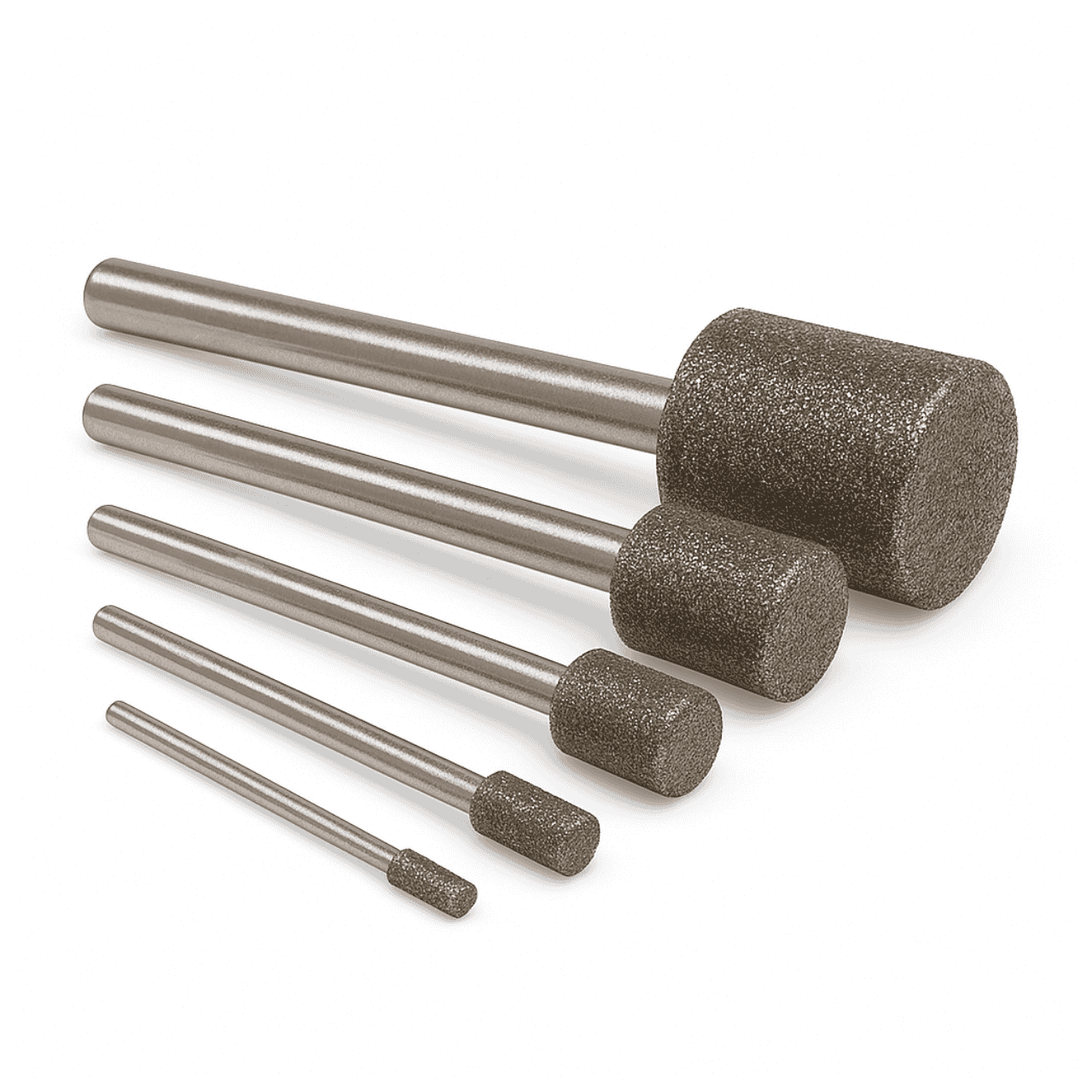

Large Diamond Cylinder Burrs

Large Diamond Cylinder Burrs

Eternal Tools

SKU:LDCB4

Our precision-ground Large Diamond Cylinder Burrs are ideal for shaping, grinding and deburring a wide range of hard materials such as glass, stone, ceramics, shell, bone, marble,glazed pottery, hard woods and enamel. The diamond coating provides a consistent, clean cut and a long working life, helping you achieve smooth, accurate results every time.

These large diamond-coated cylinder burrs are perfect for detailed work on flat or contoured surfaces. Use them to deburr, shape glass, engrave stone, sculpt or grind away unwanted material with precision. Each burr is nickel-bonded with high-quality diamond grit for durability and clean performance.

- Available in a range of diameters for versatile applications

- Precision-balanced for vibration-free use

- 2.35mm, 3mm and 6mm shank options available

- Use with a rotary hand drill, flexible shaft, pendant motor or micromotor

- Recommended for use with water for cooling and longer burr life

Every burr is carefully quality-checked and held in UK stock for fast dispatch. Whether you’re engraving glass, shaping stone, or finishing ceramic, these burrs deliver a clean, accurate cut and long-lasting performance.

***Sold Individually***

Couldn't load pickup availability

Description

Description

For different shapes, explore our full range of Diamond Burrs including Diamond Ball Burrs and Diamond Sintered Burrs.

Common Uses

- Engraving and carving glass, stone, wood, bone, ceramic

- Refinsing and finishing ceramic moulds

- Smoothing and shaping enamel or other hard materials

- Grinding away excess material from hard surfaces

- Deburring sharp edges or finishing rough areas

- Detail work on sculpture pieces

Tips for Best Results

- Always use with water to keep the burr cool and prolong its life

- Work at medium speed with light pressure – let the diamond do the cutting. Do not exceed a drill speed of approx. 12,000rpm

- Rinse and dry after use to prevent build-up and maintain performance

- Store burrs separately to protect the diamond coating

Diamond Burrs for Ceramic Mould Making

Large Diamond Cylinder Burrs are widely used by ceramic mould makers and studios for refining and repairing plaster and fired ceramic moulds. Their precision and durability make them ideal for removing seam lines, cleaning vent holes, and refining fine details without chipping the surface.

- Smooths seam lines and casting flash from slip-cast moulds

- Cleans vent holes, channels and tight internal areas

- Refines design details and restores worn or damaged moulds

- Suitable for plaster, bisque and fired ceramic surfaces

- Use wet to control dust and achieve a clean, accurate finish

Whether you’re maintaining production moulds or shaping new prototypes, these diamond cylinder burrs deliver precise, controlled material removal and a professional surface finish. Trusted by both industrial mould manufacturers and artisan ceramicists.

Frequently Asked Questions

What materials can I use these burrs on?

They’re ideal for hard materials such as glass, stone, ceramic, shell, enamel, bone, marble, composites, hard woods and similar surfaces.

What speed should I use them at?

Use at medium speed – around 5,000 to 12,000 RPM – depending on material hardness and tool type. Avoid excessive pressure.

Can I use these burrs dry?

For best results, use with water as a lubricant to keep the burr cool and extend its life.

Are they compatible with a Dremel or pendant drill?

Yes. These diamond burrs are suitable for use with a Dremel, pendant drill, flex shaft or any rotary tool that accepts 2.35mm or 3mm shanks. Please check the technical tab for the correct burrs with either a 2.35mm or 3mm shank.

Disclaimer: To the best of our knowledge, using rotary tools near or under water has never been endorsed by any rotary tool manufacturer. If you choose to drill near water or submerge attachments connected to your drill, you do so at your own risk. Please remember that mixing electricity and water can be extremely dangerous.

Technical

Technical

Diamond grit is precisely electroplated onto a steel shank

4mm

- Overall length: 40mm

- Shank: 2.35mm

- Diamond working length: 4mm

- Grit: 120

6mm

- Overall length: 45mm

- Shank: 3mm

- Diamond working length: 9mm

- Grit: 120

8mm/10mm with 3mm shank

- Overall length: 50mm/52mm

- Shank: 3mm

- Diamond working length: 10mm/12mm

- Grit: 80

10mm with 2.35mm shank

- Overall length: 50mm

- Shank: 2.35mm

- Diamond working length: 10mm

- Grit: 120

12mm

- Overall length: 52mm

- Shank: 6mm

- Diamond working length: 20mm

- Grit: 120

15mm

- Overall length: 52mm

- Shank: 6mm

- Diamond working length: 35mm

- Grit: 80

18mm

- Overall length: 52mm

- Shank: 6mm

- Diamond working length: 25mm

- Grit: 120

25mm

- Overall length: 52mm

- Shank: 6mm

- Diamond working length: 35mm

- Grit: 100

Customer Reviews

Customer Reviews

Delivery popup

£3.99 delivery via 1st Class Post

FREE on Orders over £60

Orders placed before 3pm despatched same day

£8.99 delivery next working day on orders placed Mon - Thurs before 3pm