- Home

- Abrasive Papers, Pads & Cloths

- Diamond Precision Finishing Strips

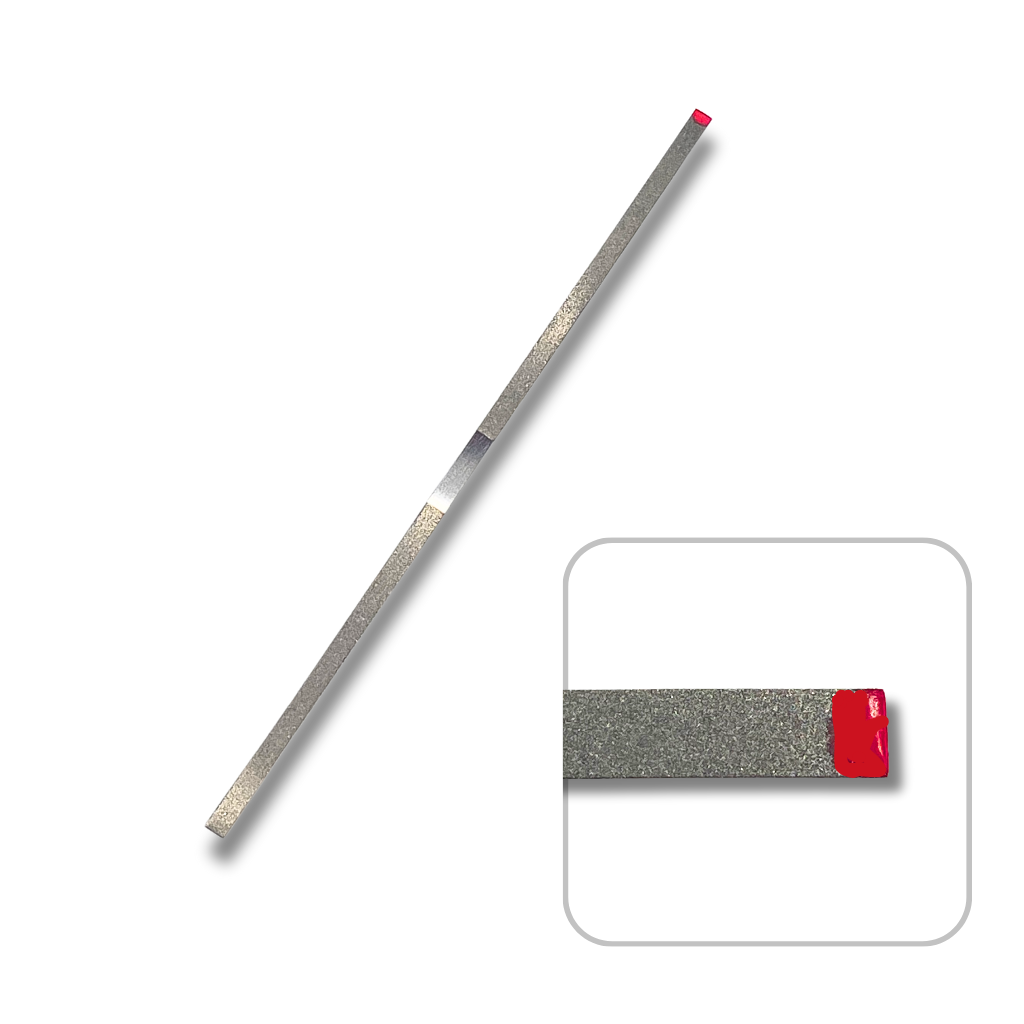

Diamond Precision Finishing Strips

Diamond Precision Finishing Strips

Eternal Tools

SKU:DFINSBL45

These diamond precision finishing strips are the ultimate abrasive solution for filing, smoothing, and polishing fine detailing, intricate designs, and hard-to-reach areas of your work. Diamond coated on one side, the diamond, flexible finishing strips are available in three different grit sizes:

- Medium: Blue (45μm)

- Fine: Red (30μm)

- Extra Fine: Yellow (15μm)

Sold individually, or as a Set of 3 (one of each grade)

Excellent for use on metals, gemstones, glass, crystal, ceramics, carbon fiber, enamel, wood, bone, resin, and acrylics.

Read the description and technical information tabs for specifications, dimensions, and full usage instructions.

Couldn't load pickup availability

Description

Description

What Materials Can Diamond Precision Finishing Strips Be Used On?

1. Gold, Silver, Platinum & Titanium: For removing tarnish, polishing, smoothing prongs and refining fine details.

2. Stainless Steel: Polishing watch cases, bezels, and bracelets.

3. Brass & Copper: Refining engraved or filigree work.

4. Gemstones: Refining facets, smoothing edges prior to setting, gentle shaping.

4. Ceramics, Carbon Fiber, Glass & Crystal, Resins & Acrylics, Enamel.

Valuable Uses In A Wide Range Of Markets:

1. Watchmaking: Use to smooth out burrs and refine edges on tiny movement parts like mainplates and bridges, polish small gears and pinions, refine and polish small screw heads and pins, remove microscopic imperfections in watch cases or bezels, and refine the edges of sapphire watch crystals.

2. Jewellery: Fine polishing of metals and gemstones, smoothing edges on delicate parts, cleaning up solder joints, smoothing prongs and settings, refining facets, and smoothing inlay work.

3. Automotive & Aerospace: Precision finishing of small engine parts, polishing metal components in tight spaces, and refining carbon fiber or composite materials.

4. Medical & Surgical Instrument Manufacturing: Polishing edges of surgical tools, finishing implants and prosthetics, and smoothing micro-instruments for precision work.

5. Optics & Glasswork:Refining edges of lenses or glass components, smoothing intricate optical instruments, and polishing fine glass details.

6. Hobbyists & Artisans: Fine detailing in wood carving and model-making, polishing and refining sculptures or miniatures, and smoothing 3D-printed parts

7. Electronics & Microfabrication:Polishing circuit board edges, refining connectors for better conductivity, and smoothing delicate electronic components.

What Is The Purpose Of The Diamond-Free Section In The Middle?

The smooth middle section ensures that surrounding materials aren’t accidentally scratched or damaged by the abrasive edges.It also acts as a grip or guiding area, making it easier to manipulate the strip without excessive friction.And in Dentistry it's for efficient Interproximal access.

How Do I Use Diamond Finishing Strips?

The best technique is to hold them by hand at each end and either saw back and forth, or fold and bend them to access curved or tight areas of work.

They can also be wrapped around a tool for extra rigidity such as tweezers, peg wood or a file.

Technical

Technical

Diamond coating bonded to Stainless Steel strips. Single-sided, non-serrated.

Blue Medium 45 microns (μm)

• Length: 148mm

• Width: 3.75mm

• Thickness: 0.13mm

• Diamond-free middle section: 15mm

Red Fine 30 microns (μm)

• Length: 148mm

• Width: 3.75mm

• Thickness: 0.12mm

• Diamond-free middle section: 15mm

Yellow Extra Fine 15 microns (μm)

• Length: 148mm

• Width: 3.75mm

• Thickness: 0.08mm

• Diamond-free middle section: 10mm

Customer Reviews

Customer Reviews

Delivery popup

£3.99 delivery via 1st Class Post

FREE on Orders over £60

Orders placed before 3pm despatched same day

£8.99 delivery next working day on orders placed Mon - Thurs before 3pm