When polishing metals, traditionally, jewellers would have used Tripoli, a rouge for polishing precious metals. Now, companies like Dialux offer a range of different products for different metals and finishes.

Dialux polishing bars, made in Germany, are premium compounds trusted by UK jewellers, silversmiths and watchmakers for achieving a superior finish. Available in a wide range of grades, they make polishing metal a much faster, cleaner process.

If you're unsure which bar to use, keep reading — or shop the full Dialux range here.

They come in small bars consisting of a compound which is uniformly blended with abrasive grit. Rather like sandpaper, by varying the size of the particles and the material, you can create different levels of abrasiveness and, therefore, different finishes on different materials.

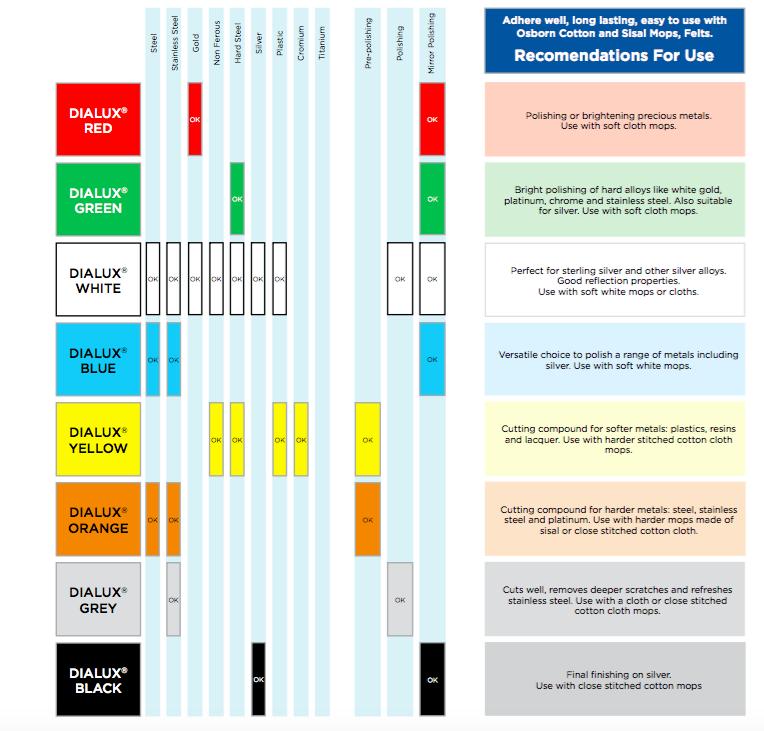

The Dialux Polishing Chart below shows the different polishes and tells you what material it's suitable for and the level of finish you will get.

It's important to say that the chart gives a guideline only. Do an experiment and see what works for you. For example, you may have a piece of nine-karat gold hammered or put through a rolling mill, which may be quite hard. In this case, you might want to use a harsher compound. Or you may have a thin 22-karat gold ring that is very soft. In this instance, you may wish to use a more gentle polish.

Dialux Comparison Chart

Here's a quick guide to help you choose the right bar for your project. Each colour is suited to specific materials and stages in the polishing process.

Dialux Compound Comparison Table

| Compound | Best For | Polishing Stage | Notes |

|---|---|---|---|

| Yellow (DLUXY) | Brass, copper, aluminium, and plastics | Pre-polish | Also works well on gold and silver |

| Grey (DLUXG) | Stainless steel, platinum | Pre-polish | Most abrasive option |

| Orange (DLUXO) | Steel, ferrous metals | Pre-polish | Use with caution on soft metals |

| Blue (DLUXB) | Non-precious metals | Polish | General-purpose polish |

| White (DLUXW) | Silver, white gold, and plastics | Final polish | Soft, high-shine finish |

| Red (DLUXR) | Gold, silver | Final polish | Rouge alternative |

| Green (DLUXV) | Platinum, titanium, chrome | Final polish | Hard metals only |

| Black (DLUXN) | Silver, Argentium silver | Final polish | Mirror-like finish |

How to Use Polishing Compounds

...ensuring you have removed any dents, tool marks, or deep scratches. These tips work whether you're polishing jewellery from your UK home studio or prepping metal in a workshop.

Start with an even, sanded surface. I like to sand down using a Sander Roll, drum or a Horotec Buff Stick, ensuring you have removed any dents, tool marks, or deep scratches. Next, apply a small amount of your chosen Dialux compound to a felt bob, cotton buff, calico wheel, belt or wheel.

Pre-polishers

Pre-polishers are the most abrasive and will remove small scratches left over from your buff stick.

The Yellow Dialux (DLUXY) is a pre-polish for non-ferrous and softer metals such as Bronze, tin, zamak, aluminium alloys and copper and also for use on plastics. Use this prior to final polishing with Blue Dialux (DLUXB). The yellow also works well with silver and gold.

The Grey Dialux (DLUXG) bar is quite aggressive, and I like that in a pre-polish. It’s great for removing scratches, particularly on platinum and stainless steel. Follow this up with Green Dialux (DLUXV)

Orange Dialux or Vornex (DLUXO) is designed for use on steel and stainless steel as a pre-polisher.

Not sure which bar to begin with? Explore the full Dialux range here and pick the right combination for your metal type.

- Go slow. As a pre-polish is more abrasive than the other bars in the Dialux range, keep the speed slow to reduce friction heat.

- Once you've removed all your sanding marks, clean your piece of work.

- It's important that you remove all traces of the previous polish.

- Keep all your mops separate, and don't allow any cross-contamination, especially on your final finishing mops, or you won't get the desired effect.

Polish

After your pre-polish, use a polish to achieve a shine.

Within the Dialux range, you have a few choices depending on your material.

The White Dialux (DLUXW) are great for silver and gold. Also, for the final polishing of plastics. Blue Dialux (DLUXB) is also great for silver and gold.

Use this with a soft mop like a soft, loose cotton buff, or if using a Dremel, you might want to use a little calico wheel.

Using the right mop or wheel is just as important as the polish. Browse our range of polishing brushes and buffs to match each Dialux bar.

If you finish off with a soft cotton mop or buff, you may find that with silver and gold, the white is sufficient on its own.

Grey Dialux (DLUXG) is designed for polishing stainless steel. It's useful to have this in your workshop, and even if you don't specifically work with steel, it's great for polishing tools such as bench blocks, punches, and hammer faces. Use with a felt wheel or bob

Final Polish: Mirror Finish

So now you've pre-polished and polished, and this may be sufficient, but when working with silver and gold jewellery, you really want that extra sparkle.

For a deep mirror finish, especially on silver or gold, our Dialux collection includes Red, Black and Green bars to take your polish to a professional level.

Black Dialux (DLUXN) is widely used by silversmiths and will give a great result on silver. Use it with a very soft cotton buff.

Red Dialux (DLUXR) is similar to traditional rouge and is, therefore, another ideal alternative for silver and gold. Again, using a soft mop.

Blue Dialux (DLUXB) is a more general finished polish and, therefore, ideal for non-precious metals such as copper, tin and brass, for instance. Use this after pre-polishing with Yellow Dialux (DLUXY)

Green Dialux (DLUXV) is a final polish designed for hard metals such as steel and platinum. Use after pre-polishing with Grey Dialux (DLUXG).

White Dialux (DLUXW) is a general final polish for most metals and plastics.

If you prepare your pieces well, then you should only need two or three polishes to get a great finish.

Cleaning up

Frequently Asked Questions About Dialux

Which Dialux compound is best for silver?

For silver, start with Yellow or Grey as a pre-polish depending on the hardness of the piece. Then finish with White, Red, or Black Dialux for a high-shine or mirror finish.

Can I use Dialux with a Dremel or a pendant drill?

Yes! You can apply Dialux compounds to small polishing accessories such as felt bobs or miniature cotton buffs, which fit rotary tools like micromotors, Dremel, Foredom or pendant drills.

What’s the difference between Red and White Dialux?

Red Dialux is similar to traditional jeweller’s rouge — it gives a deep mirror finish, especially on gold and silver. White is more versatile and also works well on plastics, delivering a softer, high-lustre polish.

Do I need to clean between each polishing stage?

Yes. Always clean your work and use separate mops or buffs for each compound. This prevents contamination and gives the best finish at each stage.

Dave Wilson of Celtic Dreams had this to say about them:

“Personally, for gold, I use yellow, white, and red. For silver, I again use yellow or sometimes grey if I want something tougher, and then white and black. I like the size of these little bars. I think they're small enough for use with the pendant drill, but still big enough for use on the bench polisher too. They're not too greasy, so they're very easy to clean up in between stages with warm, soapy water. I think they're great value, and from what I can see, they offer a good, consistent, streak-free finish. So personally, I highly recommend the Dialux range of solid polishing compounds.”

If you're ready to upgrade your polishing setup, shop Dialux polishing bars now — ideal for jewellers, metal artists and makers across the UK.