Tungsten metal is a chemical element, often referred to by its Latin name –Wolfram. It has a chemical symbol of W and an atomic number of 74.

An important member of the transition metals on the periodic table, It is solid at room temperature; with an appearance is light grey-white.

It’s extremely dense, with an atomic weight of 183.84, and has a very high melting point – boasting the highest melting point of all refractory metals. It exhibits excellent tensile strength and resistance to corrosion.

Due to its exceptional properties, tungsten metal has found uses in numerous industries, ranging from jewellery and sports to surgical instruments, aerospace engineering, high-speed tools, nuclear shielding, alloys and compounds, chemical applications and electronics.

Nowadays, tungsten is involved in research into nanowires, making it a primarily auspicious material for the future development of materials, science and technology.

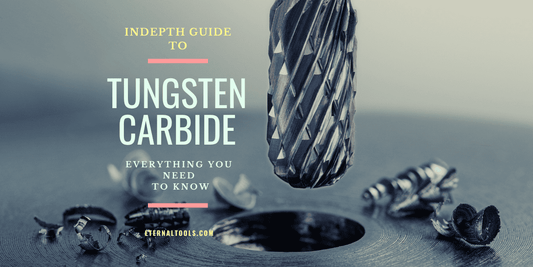

Tungsten vs. Tungsten Carbide

Tungsten refers to the individual metal whereas tungsten carbide is an inorganic non-natural chemical compound composed of equal parts tungsten (W) and carbon (C) atoms.

Tungsten Carbide (WC) is stable at room temperature and its natural occurrence is in the form of a fine grey powder. Conventionally, tungsten carbide powders are produced by heating a mixture of tungsten powder and carbon black.

Using the process of sintering this powder can then be pressed and formed into a variety of shapes which are then used in machinery, cutting tools, bullet shells, and jewellery, to name but a few.

- Tungsten carbide is so hard, the only natural material that can scratch it is a diamond.

Accessibility of Tungsten

Tungsten is an Earth’s crust metal found in compounds and requires purification before use. It is a relatively rare metal element thought to be formed through explosions of supernovas. Out of every 1000 kilograms of the Earth’s crust, there are just 1.25 grams of tungsten.

The Properties of Tungsten Carbide

- 1. Platinum-Like Behaviour.

Tungsten carbide catalyses the formation of water from hydrogen and oxygen at normal temperature, the reduction of tungsten trioxide by hydrogen in the presence of water, and the isomerisation of 2,2-dimethyl propane to 2-methyl butane.

This catalytic behaviour, which is usual in platinum, is not exhibited at all by tungsten. The surface electronic properties of tungsten are therefore modified by carbon in such a way that they resemble those of platinum.

- 2. Strength.

The Tensile strength of tungsten metal is 980 megapascals (MPa), which makes it much stronger than cast iron (200MPa), structural steel (550MPa) and even stainless steel (860MPa). Tungsten is the strongest naturally occurring metal on Earth.

- 3. Hardness.

Tungsten carbide is known for its hardness, ranking about 9 to 9.5 on the Mohs scale. Which is second only to the industrial diamond and is proven to last longer than most metals. Tungsten carbide is so hard, the only natural material that can scratch it is a diamond

- 4. Low Thermal Expansion.

Compared to common manufacturing materials (e.g. steel), tungsten has added stability under extreme heating conditions. The structural solidity of tungsten carbide is different from other metals and is especially useful when rigidity is required at high temperatures such as in tungsten carbide cutting tools or jet engine turbine blades.

- 5. High Density.

Tungsten benefits from a very high density. At 19.3 g/cm3, tungsten is amongst the highest of all other metals. As a result, tungsten can hold much more weight in smaller sizes.

For example, tungsten carbide is a fantastic option for making racing car ballast, aircraft ballast and kinetic munitions – which must be small and streamlined, and capable of transferring a huge amount of energy.

- 6. Resistance to High Temperatures.

Tungsten carbide has a high melting point (5,200°F) which makes it an excellent material for high-temperature environments.

- 7. Electronic Structure.

Tungsten metal is widely used in the electronics industry due to its high conductance, inertness and environments involving high levels of radiation. For this reason, along with its very high density, tungsten is one of the main sources of metal for X-ray targets because the relatively inert, very high-density material is difficult for X-rays to penetrate.

- 8. Corrosion-Resistance.

Tungsten carbide is highly resistant to corrosion and can be used in a wide range of corrosive environments and outdoor applications.

Application & Uses Of Tungsten Carbide

More than half of the world’s tungsten is utilised in the production of hard materials, such as tungsten carbide –the hardest material known.

This exceptionally hard tungsten compound is priceless in the construction of cutting, drilling, filing and boring machines – creating components that take significantly longer to wear down, work much more effectively, and greatly boost the cost-effectiveness of the tools and machinery in which tungsten carbide is used.

Carbon and tungsten together create an alloy that is resistant to heat, rust, scratches, and marks.

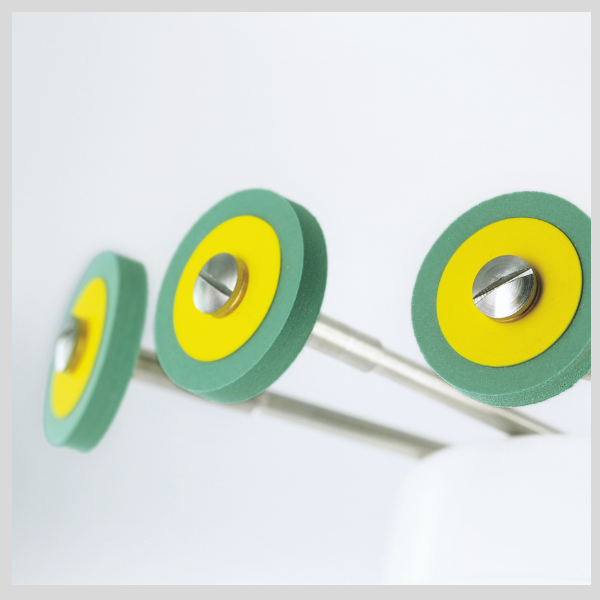

Tungsten carbide can be grafted to other metals and can be sharpened with high precision using diamond tooling such as these Phenolic resin bonded diamond grinding wheels for sharpening tungsten carbide gravers.

Tungsten Carbide in Jewellery Making

The production of jewellery is among the newest applications for tungsten carbide that’s gaining a reputation. Tungsten carbide wedding bands, and scratch-resistant watch cases, watch bands and watch buckles have gained in popularity as it is virtually impossible to scratch, have a beautiful shine and are less expensive than other metals.

The affordability, strength and resistance to scratches and corrosion make Tungsten carbide rings a unique choice. However, once made, tungsten carbide rings cannot be resized easily due to their brittleness.

Tungsten carbide rings are often referred to as ‘tungsten’ rings for simplicity. A 100% tungsten ring, as a standalone metal, is quite difficult to construct into a ring and would not be as durable or corrosive resistant as a tungsten carbide alternative.

However, one has to make sure that they are indeed purchasing tungsten carbide. A good indicator of this is the price; low-priced tungsten carbide rings are often made of weak materials.

The step-by-step crafting of tungsten carbide rings is listed below:

➢ Pure tungsten metal and carbon are ground in powder form and then put inside a ring mould. The powder is compressed and heated at 1400°C. This process is called sintering.

➢ The next step is polishing. After the sintering process, the raw black alloy is passed through multiple steps of polishing. Due to the high strength of tungsten carbide, diamond paste for metal must be used in place of regular polishing wax or compound. Starting with 90 microns, the number is then reduced in each polishing phase until a fine finish is achieved. A 0.5 micron paste is used for a superior mirror fine finish.

➢ To achieve a satin, brushed or matte finish the ring can be abraded with a diamond coated disc or wheel in a rotary tool, or a flat lap used on a lapidary machine.

➢ Setting stones into tungsten carbide rings requires the use of a high-power laser machine. Due to the non-malleable property, tungsten carbide rings are cut with precision to the exact diameter of the stone to ensure it is held securely.

After the stone is placed in the ring, a stainless steel setting is placed on top to further secure the diamond in its place.

➢ Tungsten carbide rings are often inlaid with other materials such as silver, gold, platinum, ceramic, stone and wood, or laser engraved with designs.

Tungsten Carbide and Metal Cutting Tools

Cemented carbide is used to make drilling and mining tools that are required for various construction applications and account for the greatest use of the material anywhere in the world. About 68% of the market is based on mining tips, drill bits, and other cutting, milling, and mining tools.

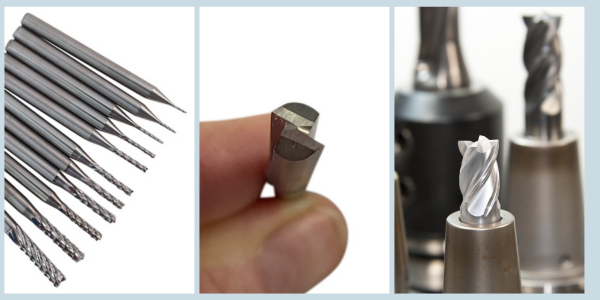

High-precision Tungsten carbide machining tools are preferable to HSS (High-Speed Steel) because of their superior hardness, high wear and tear resistance, and ability to withstand higher working temperatures, allowing for higher cutting speeds and feed rates.

Tungsten carbide tools are essential when maximum precision and high cutting speeds are required and are often used on very hard metals that can be difficult to manipulate, titanium for instance.

Carbide tools such as drill bits, gravers, centering tools, cutting tips, end mills and carving burrs, saw blades, lathe bits, and router bits are extremely long-lasting and will cut through the hardest of metals. However, they still need to be replaced over some time.

- Tungsten Carbide drill bits

- Tungsten carbide cutting and carving burrs

- Tungsten carbide end mills, milling cutters

- Tungsten carbide engraving cutters

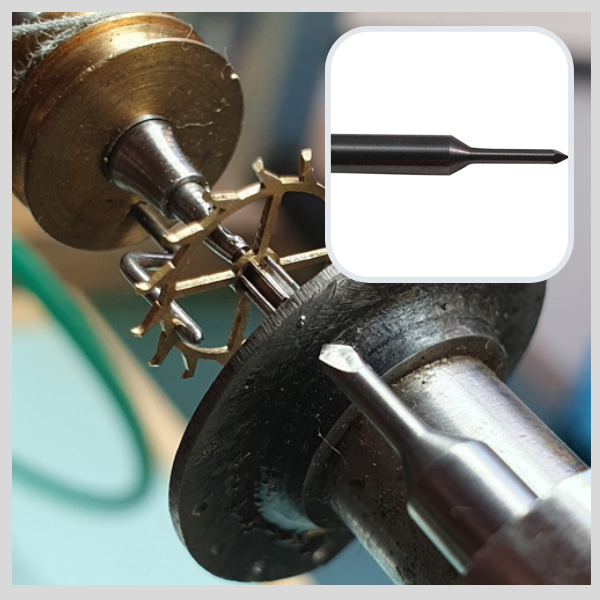

- Tungsten carbide gravers

- Tungsten carbide engraving tools

- Tungsten carbide CNC router

Tungsten Carbide Drill Bits

Tungsten Carbide Cutting and Carving Burrs

Tungsten Carbide End Mills, Milling Cutters

Tungsten Carbide Engraving V-Cutters

Some tools are coated carbide inserts mounted on a steel shank and others are solid tungsten carbide.

Some tools are coated carbide inserts mounted on a steel shank and others are solid tungsten carbide.

Tungsten Carbide Gravers

A large percentage of the tungsten volume in cemented carbide is presently used in wear parts applications, for a wide variety of products from very small to large and heavy products, such as ball-point pens, dies, punches, or hot rolls for rolling mills in the steel sector.

Recycling Tungsten carbide: The recycling incentives for cemented carbide are very encouraging, which offers yet another reason to use it in mass. Even Carbide recycling companies pay reasonable prices for scrap. This ultimately keeps the production costs low while allowing workers to use the highest quality tools and accessories in their daily life.

The scrap tools of cemented carbides are extensively utilised in the manufacturing, petrochemical, construction, gas drilling and mining sectors. About 40–95 weight percentage becomes available for recycling and reuse when scrapped.

Tungsten Carbide and Surgical Tools

The use of tungsten carbide tipped surgical tools in the Medical industry means superior quality tools for intricate and precise tasks. Using Tungsten carbide gives blades and tips sharper, finer, and more precise cutting edges, as well as the other advantages of longevity, hardness and no corrosiveness.

Sports and Leisure Uses for Tungsten Carbide

Other tungsten carbide applications are in the use of trekking and ski poles, cleats and studs for sports shoes, and the manufacturing of fishing weights, horseshoe pins, and Tires which provide better traction on ice for cars, motorcycles and bicycles.

Electronics

Tungsten carbide is an excellent conductor and has relative chemical inertness. Tungsten's tolerance to intense heat makes it an ideal material for use in the electronics industry in electrodes and electron microscopes.

For example, tungsten is used as an interconnect material in ICs (Integrated Circuits), between the silicon dioxide dielectric material and transistors.

Tungsten is one of the main sources of X-ray targets due to its unique electronic structure.

Nuclear

Tungsten carbide is an effective neutron reflector. It was used during early investigations into nuclear chain reactions, particularly for weapons.

Aeronautical industry

Thermal spray coatings of tungsten carbide are applied in commercial aircraft applications to replace chromium electroplate due to environmental and economic considerations.

Conclusion

Tungsten carbide is a valuable alloy made from tungsten, which is a very rare metal. Its unique properties are extreme hardness, excellent conductivity, resistance to corrosion, high density, low thermal expansion and resistance to high temperatures.

Used in many industries, for many uses such as jewellery, surgical tools, drilling and mining tools, mill merchandise and sports usage. Also, you may be interested to read 7 Facts About Tungsten Carbide Burrs And How To Use Them.

The scrap of tungsten carbide products is extensively utilised in the manufacturing, petrochemical, construction, gas drilling and mining sectors. The comparatively lesser price of tungsten carbide as compared to other metals and alloys provides new avenues for its utilisation in the modern world.