1. When Did Your Interest In Horology Begin?

Mechanical devices have always interested me. Being born in the late thirties, when I was a teenager in the early fifties, cars and motorcycles were cheap and sufficiently simple mechanically that one could perform repairs without needing expensive equipment.

At age 30, 1968, I was working as a heavy equipment mechanic, repairing large construction equipment and trucks. An 1880s Waltham watch that I’d owned for years had stopped running.

Over the years, reading the “Popular Mechanics” magazine, I’d seen an advertisement for a correspondence course to learn watch repair. So I decided to learn something new.

Can’t recall the cost, but it wasn’t a great amount and was payable monthly. So that was the start. Over the years, I went to a few one-day, brand specific classes, but never had any formal classroom training, although the beginning correspondence course was well monitored.

Beyond that, I’ve read many books and of course repaired a great many watches.

2. Do You Have A Shop Or Home Workshop?

In the mid-seventies, living in Hawaii, I had my own shop for about two years. Other than that, except for about the last 15 years, I’ve mostly done watch repair part-time. There was a few year period in the eighties where I worked in a large shop with several other watchmakers.

The work was a good learning experience, but not very remunerative. My last “real” job was as a tool maker in a small manufacturing plant. For more than ten years, after retiring from manufacturing, I worked part-time at a local family-owned jewelry shop. The shop closed about two years ago, so now I work at home.

I have a nicely equipped shop, with a well tooled watchmaker’s lathe and a small vertical mill and all the normal watchmaker’s tools. Actually, while working the the jewelry shop, I also had the shop at home, so now I have the contents of two shops—two cleaning machines, three timers, six different presses, staking tools, jewelling tools, on and on.

3. What Are Your Favourite Timepieces?

Although I’ve never owned one, I always thought the 18 size 1892 Waltham was a beautiful watch. Most American 18 size watches are full plate models with the balance cock screwed to the back plate. The ‘92 Waltham is a 3/4 plate design and in the high grade versions, very beautifully finished.

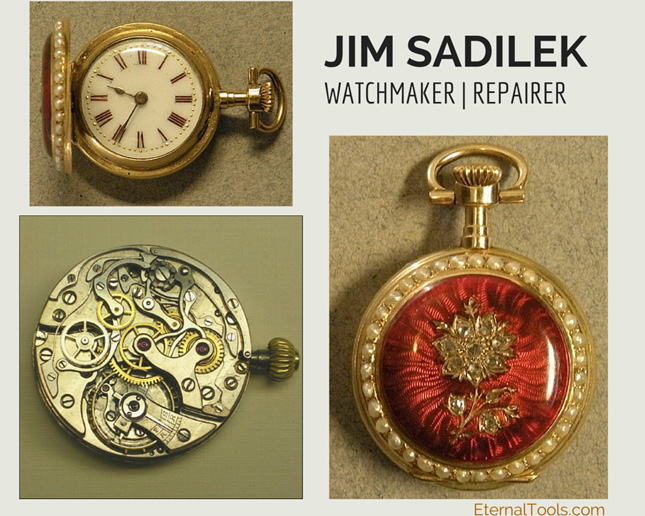

Above image: front and watch face of a Vacheron & Constantin ladies pendant watch, circa 1910. 18k gold with red guilloche enamel decoration. Chronograph movement, Valjoux caliber 23, circa 1930.

4. What Tools Could You Not Live Without?

All of them, although some I don’t use for months at a time, or even years, I wouldn’t want to give up any.

The brass tweezers are what I use most often, but I wouldn’t give up the other dozen plus tweezers that stay in the drawer except for for special jobs.

Having bought several watchmaker’s estates over the years, I've some rather strange tools, many that are well over a hundred years old, but still usable and often used. There is hand vice that I seldom use, that I’d have to guess is past two hundred years old.

5. What Do You Find The Most Difficult Task?

Most difficult, perhaps as I age, is to service the very tiny ladies watches. This is not the common 5x7 or 6x8; I grew up on these. I’m referring to the 5 ligne round Omega, that is too small for any of my movement holders, or my wife’s Movado caliber 9M which at 3-3/4 x 8 ligne is thought to be the smallest production movement with the wheels in a single plane. The Jaeger LeCoultre caliber 101 is smaller, but the wheels are on two levels.

There isn’t anything that comes to mind that is particularly frustrating, unless sometimes getting chronograph seconds hands exactly zeroed can be a trial.

6. Do You Feel Concerned About The Future Of Your Trade?

The future of our trade, which is very nearly 500 years old, is very concerning. The Swiss industry, by their restrictive policies and monopolization of service, seems determined to destroy the trade and to turn modern watch service into an assembly line operation with minimally trained operatives.

Fortunately, for those of us who have the skill and background, not to mention access to vintage parts, there is a lucrative market in vintage and antique restoration.

7. What’s Next?

Learning more about cylinder escapement repair procedures is a current goal. Most watchmakers avoid the cylinder watches like the plague, but there are tens of thousands of them out there in the hands of people who would like for them to run. Most started life as cheap timepieces, but not all.

Last year I serviced a beautiful solid 18K gold and enamel ladies Vacheron & Constantin pendant watch with a cylinder escapement. Those of us who study horological history are aware that Breguet made many cylinder escapement watches. There were also other fine makers of cylinder escapement watches in the eighteenth century.

-------

Thanks for the very interesting interview Jim, you can discover lots more on Jim's website: www.ccwatchmaker.com