Metal parts are commonly used in various industries, from automotive to aerospace. During the manufacturing process, sharp edges and rough surfaces, known as burrs, can form on these parts, affecting their overall quality and performance.

Deburring is a crucial step in the production process that aims to remove these unwanted burrs and ensure smooth surfaces. In this blog post, we will explore deburring, its importance, different methods of deburring, and the tools used for this process.

Deburring: Understanding the Basics

What is a Burr And How is it Formed?

When metal parts are machined, cut, or shaped, the cutting tool removes material to achieve the desired shape. However, this cutting process can often result in the formation of burrs, which are small ridges or sharp edges of unwanted pieces of material that remain attached to the metal surface. (to add to the confusion, the carbide and diamond tools often used for removing these are also known as burrs or burs)

The formation of burrs is a common occurrence in various machining processes, especially when working with sheet metal or machine parts.

Burrs can negatively impact the quality of the part in several ways. They can hinder the assembly process, cause safety hazards, compromise the performance of the part, and even affect the overall aesthetic appeal of the product. Therefore, removing burrs is an important step to ensure the functionality and quality of the metal part.

The Importance of Deburring

Deburring is the process of removing burrs from metal items to achieve smooth edges and surfaces. It is a crucial step in the manufacturing process, as it significantly improves the quality of the part. By removing these sharp burrs, the overall performance and functionality of the metal part can be enhanced, ensuring a high-quality finish.

Aesthetically, deburring also plays a vital role in enhancing the product's appearance. Smooth surfaces and edges contribute to the overall visual appeal, making the part more appealing to customers and the user.

Moreover, eliminating burrs also eliminates potential safety hazards, as operators and end-users can avoid accidental cuts or injuries caused by sharp edges.

Different Methods of Deburring

Deburring can be accomplished using various methods, each suited to different types of burrs and materials. Let's explore some of the most common techniques used in the industry:

1. Manual Deburring

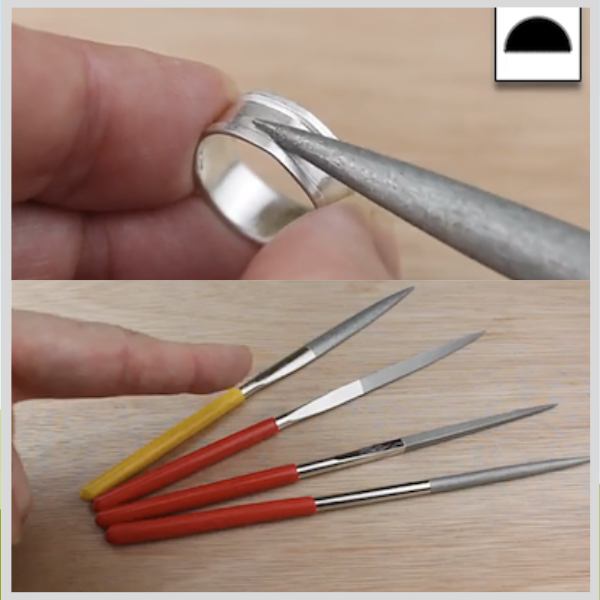

One of the oldest and simplest forms of deburring is manual deburring, which involves using hand tools to remove burrs. This method is often used for small parts or in small shops where automation is not feasible.

Manual deburring tools, such as files, abrasive belts, or even sandpaper, are used to grind away the burrs by hand carefully.

Although time-consuming and labor-intensive, this method provides precise control and is effective for removing burrs from hard-to-reach areas or the surface of a workpiece that is tiny in size and therefore requires a more precise approach. For instance, modelmakers of miniatures, micro engineers, watchmakers and jewellers will often hand deburr.

2. Mechanical Deburring

Mechanical deburring involves the use of machines and equipment to remove burrs from metal parts. It is a standard method used in large-scale manufacturing processes where a high volume of parts needs to be deburred.

Mechanical deburring processes can include abrasive media, abrasive materials, or rotary tools to remove burrs and achieve a smooth finish.

These processes can be performed using various machine tools, such as vibratory deburring machines or tumbling machines, which utilize mass finishing to simultaneously treat multiple parts.

3. Thermal Deburring

Thermal deburring, or the "Burr-Off" method, is a specialized deburring technique primarily used for intricate parts with complex geometries. It involves subjecting the parts to a controlled explosion inside a specially designed chamber.

The formation of burrs is eliminated by the thermal energy generated during the process. The explosive mixture within the chamber dislodges and removes the burrs without causing any damage to the machined surfaces. This method is highly efficient for deburring small or hard-to-reach areas.

4. Electrochemical Deburring

Electrochemical deburring is a precise and efficient deburring method that relies on a chemical reaction to remove burrs from metal parts. It utilizes an electric current to dissolve the burr or affected area, leaving behind a smooth surface.

Electrochemical deburring is particularly effective for complex shapes and delicate parts, as it selectively removes the unwanted material without causing any damage to the surrounding areas.

This method is often used in industries such as aerospace and electronics, where high precision and a high-quality finish are essential.

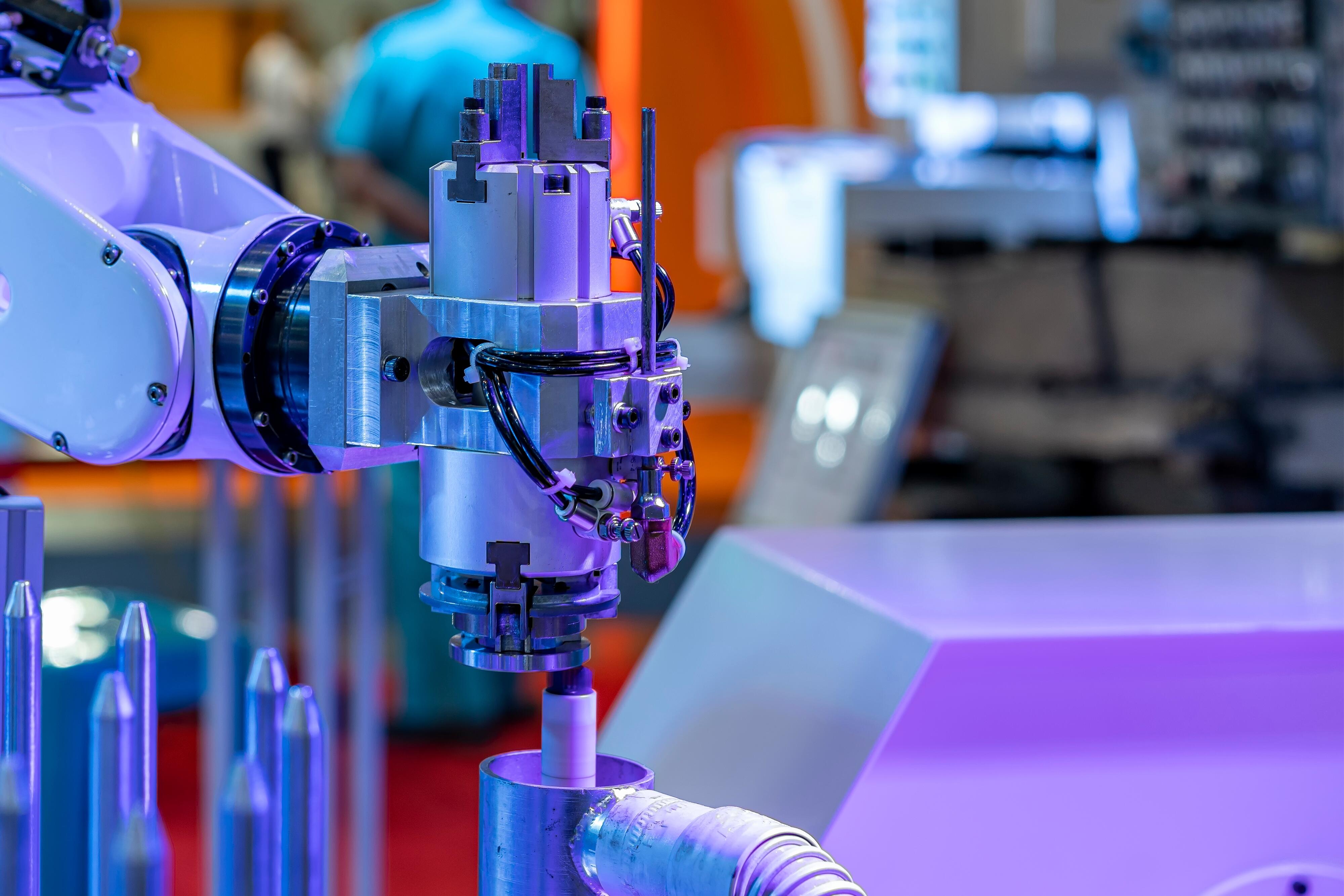

5. Robotic Deburring

In recent years, advancements in automation technology have led to the development of robotic deburring solutions.

Robotic deburring involves using a robotic arm equipped with deburring tools to perform precise and consistent deburring operations.

This method is widely used in large manufacturing facilities and machine shops where high-speed and accurate deburring are required.

Robotic deburring offers the advantage of increased productivity, as the robotic arm can work continuously without the need for breaks or rest, ensuring consistent quality in the finished products.

Deburring Tools: Achieving a Smooth Finish

To effectively remove burrs and achieve a high-quality finish, various tools are used depending on the method of deburring. Let's explore some of the standard tools employed in different deburring processes:

1. Hand Tools

Hand tools such as files, scrapers, and sandpaper are often used in manual deburring to remove burrs by hand. The use of hand tools allows for precise control and enables operators to reach small or complex areas.

These simple tools are cost-effective and readily available, making manual deburring accessible even in small-scale operations.

Flat surfaces can easily be smoothed out with some sandpaper, an abrasive diamond hand pad, grinding pads or abrasive cloths.

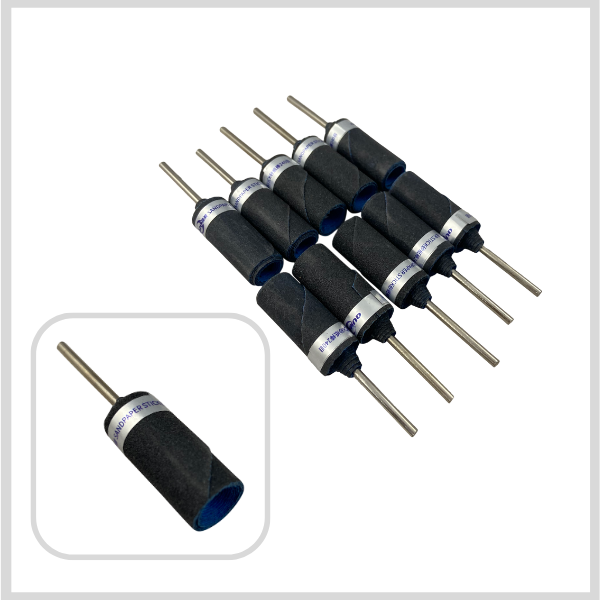

2. Abrasive Belts

Abrasive belts are commonly used in mechanical deburring methods, where the part is passed through or against a rotating abrasive belt to remove burrs.

This process is often automated and allows for a high volume of parts to be deburred quickly. Abrasive belts are available in various grit sizes to achieve different levels of surface finish.

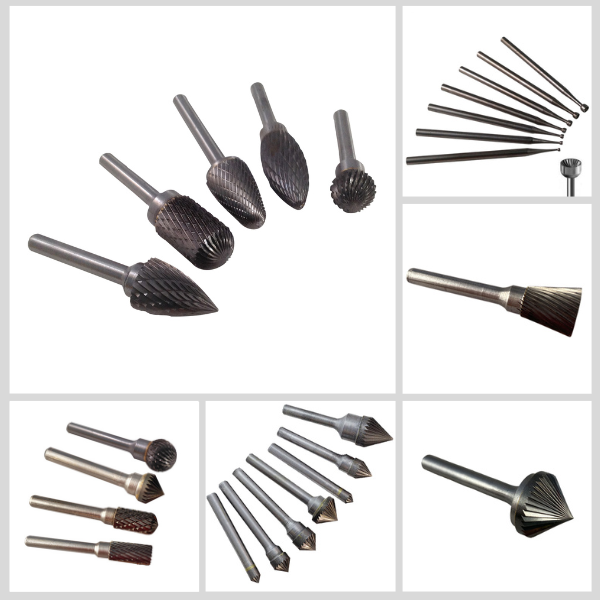

3. Rotary Tools

Rotary tools, such as carbide burrs, diamond burrs or grinding stones, are frequently used for mechanical deburring.

These tools are attached to a rotary machine and are capable of removing burrs quickly and efficiently.

Carbide burrs, in particular, are known for their durability and ability to tackle even the toughest burrs on a metal surface.

Diamond Burrs are known for their ability and strength to smooth out burrs on a glass, ceramic or stone surface.

Rotary tools provide versatility in different shapes and sizes, enabling operators to reach intricate areas.

4. Vibratory Deburring Machines

Vibratory deburring machines are commonly used in mass-finishing processes. These machines utilize a vibrating motion to generate friction between the burrs and the abrasive media, effectively removing the unwanted material.

Vibratory deburring machines are suitable for various metal parts and can achieve consistent and uniform results.

5. CNC Machines

Computer Numerical Control (CNC) machines are widely used in the manufacturing industry for various operations, including deburring. A CNC machine can be programmed to perform precise and repetitive deburring tasks, ensuring consistency and accuracy.

These machines are capable of removing burrs, often using carbide end mills from complex geometries and are often utilized in high-precision applications.

Choosing the Right Deburring Method for the Job

With different deburring processes and tools available, it is important to select the most appropriate method for the project's specific requirements. Several factors should be considered when choosing the deburring method:

1. Part Material

The type of material being used for the part is a vital consideration, as different materials require different deburring techniques. For example, metals like aluminium or stainless steel may require a separate deburring method compared to plastic materials, stone, glass or ceramic.

2. Type of Burr

The nature and severity of the burr also play a significant role in selecting the appropriate deburring method. Sharp burrs may require a more aggressive deburring approach, while minor burrs may only require a gentle treatment.

3. Machine Configuration

The availability of specific deburring equipment should also be considered. If a particular machine or tool is already in use for other processes, incorporating deburring into the existing machine configuration may be more efficient and cost-effective.

4. Operator Expertise

The machine operator's or personnel's skill level and expertise in the process should also be considered. Some deburring methods may require specialized training or experience to ensure optimal results and minimize errors.

5. Size and Shape of the Part

The size and shape of the part to be deburred should be considered when selecting the deburring method. Large parts may require a different approach compared to smaller, more intricate parts. Complex shapes may also necessitate the use of specific deburring tools or techniques.

By carefully evaluating these factors, manufacturers can choose the most suitable deburring method that will effectively remove burrs and achieve the desired level of quality for their products.

So, what have we learnt about Deburring?

1. Deburring is an essential process in the manufacturing industry, aimed at removing burrs and achieving smooth surfaces and edges on metal parts.

2. It plays a crucial role in enhancing the overall quality and performance of machined parts while ensuring their aesthetic appeal.

3. With different methods and tools available, manufacturers can choose the most appropriate deburring technique for their specific requirements. Whether it's manual deburring, mechanical deburring, thermal deburring, electrochemical deburring, or robotic deburring, each method offers unique advantages and is suited for different types of burrs and materials.

4. By investing in the correct equipment and employing the right deburring method, manufacturers can ensure the production of high-quality parts with a smooth finish.