Will Beattie enjoys his amateur radio hobby and makes and creates his own printed circuit boards for some of his projects. His latest style of building is what he likes to call "Manhattan" because it looks a bit like a city with skyscrapers. Read on to find out what tools Will used and how he did it....

What Tools Did Will Use?

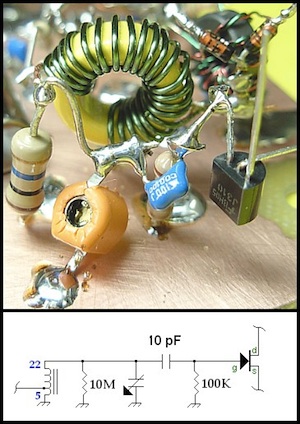

- Double sided copper clad printed circuit board with various electronic components on it.

- Pads on the board

- 5mm diamond core drill

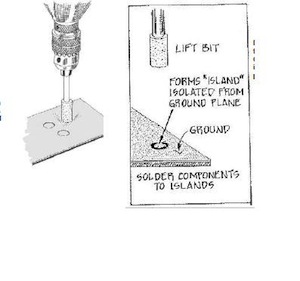

This method involves taking a piece of double sided copper clad printed circuit board and mounting all the electronic components on to it. In order to mount them, he needed something to make little “islands” or pads on the copper board in order to “isolate” them and the 5mm core drill tool was ideal in achieving this. See the picture below:

The silver “blobs” that you see are the “islands” or pads which he then attaches the components to by soldering them in place. Some individuals prefer to make up a formal printed circuit but this method is now well practiced and, most importantly, it works and is quick.

The silver “blobs” that you see are the “islands” or pads which he then attaches the components to by soldering them in place. Some individuals prefer to make up a formal printed circuit but this method is now well practiced and, most importantly, it works and is quick.

Will goes on to say...

Will Beattie

If you have a similar hobby to Will and are looking to drill through fibre glass Printed Circuit Boards (PCB) we have a whole range of diamond core drills suitable for the job plus a range of tiny Tungsten Carbide Micro Twist drills as small as 0.1mm. Here, take a look:

We would love to hear from you if you use our tools and would like to have your work featured in an article or on our gallery page. Drop us a line