When did your interest in horology begin, and who or what inspired you?

Ever since I've been young I've always been compelled to find out how the things around me worked. I would take anything apart I could get my hands on and hopefully put it back together.

When I was 10, my parents found me in my room with a new toy helicopter in pieces all over the floor - and me with a screwdriver in hand. Needless to say, they were less than impressed, but I can thank them for realizing that my habit of taking things apart wasn't just malicious and then supporting me by letting me use the garage to build whatever my imagination could come up with.

When I was sixteen, my obsession with watches really began to take hold. I began as an enthusiast - cruising forums and reading articles online to learn everything I could about watches. My two interests merged the day when I bought a cheap set of tools off of eBay and I opened my first mechanical watch; a Seiko Monster.

When I first explored the inside of the watch I was fascinated, and before I knew it I was enrolled in watchmaking school in Switzerland, 6 500km away from home. Making the transition from creating things out of construction materials, to being able to precisely machine parts and finish components has been an extremely rewarding journey.

What are your favourite timepieces and why??

I have always loved simple watches and have been fascinated and motivated by the work of the Independent watchmakers (AHCI, etc) because the watches are so pure and largely reflect a single person's idea and vision. When it comes to manufacturers, my three favourites are A Lange & Sohne, Jaeger LeCoultre and Jacquet Droz. A great watch that has consistently been my favourite for the past few years is the JLC Ultra thin Moonphase in 39mm - I have always had a preference for simple, well-executed watches.

What tools could you not live without?

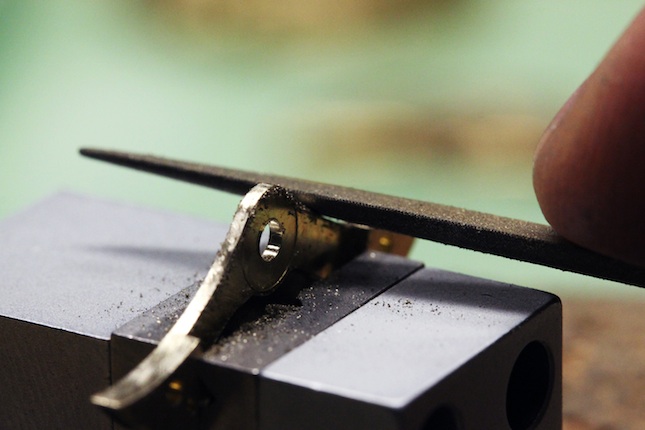

One of the many essential tools I use is the diamond lap. Almost every tool that comes into contact with the watch also needs or can be redressed with the diamond lap. It's possible to reshape screwdrivers, tweezers and carbide cutters as well as sharpen drills, and it's useful for a variety of other applications. Being able to cut and reshape materials like ruby sharpening stones at any time is invaluable.?

Also worth mentioning are screwdrivers and tweezers. The moment the screwdrivers arrive from the shop, they need to be reshaped to fit the screws you plan on working with - having in excess of 20-30 screwdrivers is not uncommon for a watchmaker. Tweezers often need to be reshaped after they are bought and ground on all sides to ensure the tips meet and can provide a good grip on tiny parts.

Depending on what kind of work I am doing it is not uncommon to touch them up three or more times a day. If you get lazy with maintenance, you may find yourself spending too much time on the floor looking for parts (time when you could be on the bench).

Do you feel concerned about the future of the watch industry, and if so, why?

It's an exciting time in the watch industry because so many changes are happening; people have called it the renaissance of watchmaking. There are many interesting technical developments in materials like silicon parts and incredible new complications, but at the same time, there are threats as well - a potentially large one being the smartwatch which has just begun to enter the market.

Overnight, the quartz crisis of the 1970's cost thousands their jobs; machines and tools were abandoned and the entire industry was shaken. With the release of the smart watch it is not surprising that some are concerned that the mechanical watch will begin to fade - I personally disagree.

I don't believe that the current market for mechanical watches overlaps with those customers who will wait in line to buy a smart watch. Watch collectors and enthusiasts are not looking for a watch that delivers text messages or orders a pizza.

I believe that, like me, they are looking for something unique, something that reflects the qualities of art, science and engineering and, of course, a watch that is aesthetically appealing. I may be old-fashioned, but winding a watch every morning and watching it come alive must certainly be more rewarding than plugging a watch in at the end of the day.

The current market for high-end watch sales has been strong, and I feel positive about the future of this industry.

If there was something you could change about the watch industry, what would it be?

It would be fantastic if it were easier to educate the customers, the buyers and end-users of watches, about quality in watchmaking.

Many still believe their $1000 watch was romantically made in the Swiss highlands by an ageing watchmaker. I think many have trouble understanding where the value is in haute horlogerie, and it seems like it will always be difficult to show customers the blood, sweat and tears involved in chasing flawless quality.

What do you find the most frustrating or difficult repair job or task?

The progression of learning skills in watchmaking can be extremely frustrating; it seemed, at least for me, that for each new skill, there was a new obstacle to overcome. For skills like burnishing and hairspring manipulation, it can seem like progress is nearly non-existent until one day, it just sort of ‘clicks’.

I think the reason watchmaking appeals to those who have chosen it as a career is that there is no natural finite end to the skill development. You could spend your entire life trying to master this career.

In reality, you could spend years studying the theory of gears and their interactions inside the watch. To even attempt to master watchmaking in itself is a great challenge, also to try to master the related professions: dialmaking, casemaking, polishing etc. is something that I imagine would take many lifetimes.

What’s next? Any interesting projects or dreams you wish to fulfill?

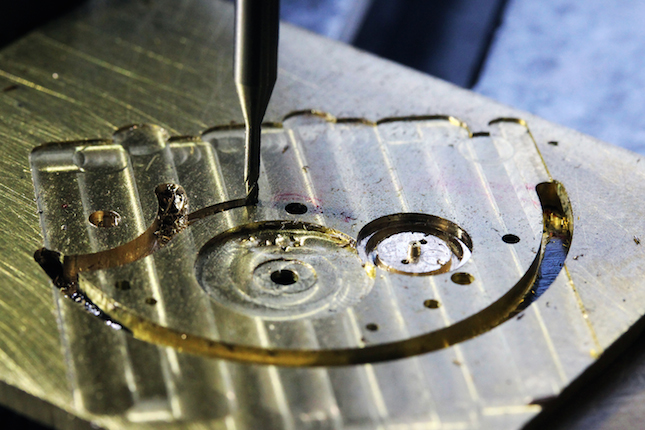

In the longer term, I hope to set up my own workshop. I’ve been gathering tools and machinery to set up an independent shop in Canada and could not be more excited. The prototyping on my first watch has been going really well (as well as prototyping can go!) and I would love to one day be completely independent and produce my own watches.

There is something so special about a watch in which all aspects, design, construction, and even finishing, are performed by one person. I know it is going to be a long road actually to be self-sustaining, but I know it will be worth it – having the freedom to be creative in my work is very important to me.

What a great interview! My thanks to Brad and Taylor Horology. Find out more about Brad on his excellent website: http://taylorhorology.com